PREMA – PREdictiveMAintenance

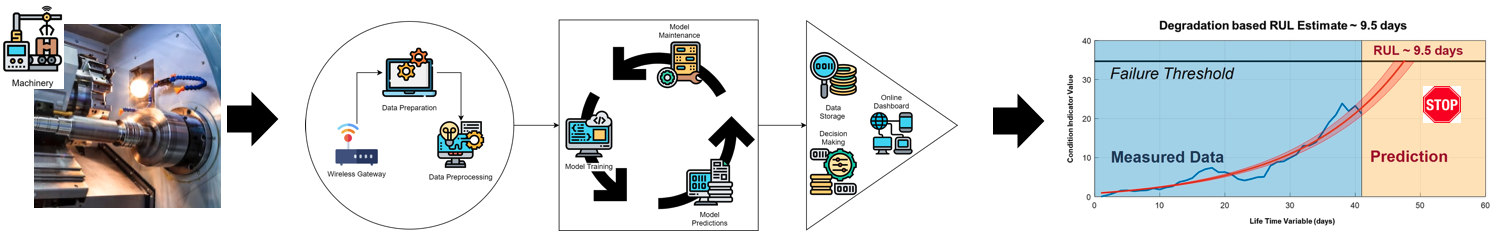

Project started in 2020, with main goals:

- Being the enabler of Predictive Maintenance within the Industry 4.0 paradigm for Bottero glass handling machinery and Brovind sorting machines

- Usage of IoT and Data Analysis techniques to extract information and gain knowledge about the real-time behavior of objects subjected to vibrational stresses

- Minimize damage and allow intelligent predictive analysis

Project included in the 2016 strategic research agenda of the ICT Innovation Hub, funded under the Piedmont POR FESR 2014-2020 and carried out with the contribution of the Fondo Europeo di Sviluppo Regionale (FESR), the Italian State and the Piedmont Region.

DISLO-MAN

Dynamic Integrated ShopfLoor Operation MANagement for Industry 4.0

ICT platform for integrated dynamic and autonomous management of high-level automation production operations aimed at optimizing resources (people, materials, production systems).

Project financed under POR 2014/2020 of the Piedmont Region, FESR (European Regional Development Fund) and MIUR program – Piedmont Region – Action 3 – “Intelligent Factory”

For more information visit the website disloman.it

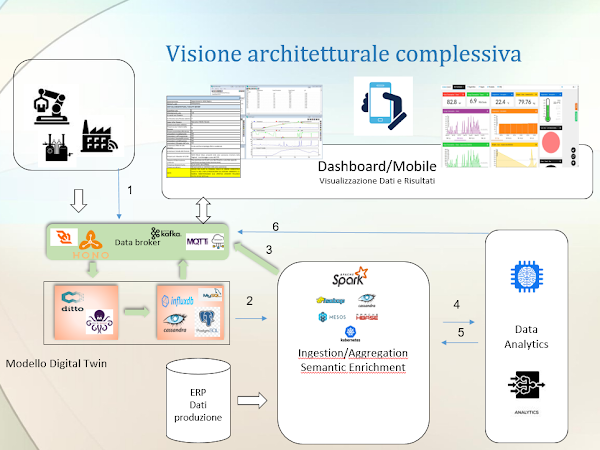

ICS – MSC

Industry 4.9 Complex Solution for Manufacturing Supply Chain

The ICS-MSC project aims to create a flexible platform for hosting Digital Twins that can represent products and / or production processes in real time.

Real-time simulation of the production process (mechanical / intra-logistic) and packaging / storage in the two use cases using data from production systems and supplied by IoT sensors and gateways and analyzing the behavior with Artificial Intelligence techniques at purposes of predicting any deviations, drops in performance and product quality problems.

Project funded under the POR 2014-2020 of Piedmont and carried out with the contribution of resources from the European Regional Development Fund (ERDF) of the Italian State and the Piedmont Region.

Roller-bearing

Innovative research related to the use of vibration signals for the prognostic / early identification of the type and severity of damage occurring to roller-bearings through the implementation of machine learning and/or neural networks algorithms.

Two data sets have been evaluated:

- Data collected over a rig set up at Department of Mechanical and Aerospace Engineering lab of Politecnico di Torino,

- Data collected in the test rig the NSF I/UCRC on Intelligent Maintenance Systems (IMS).

As a result, 97.71% of average prediction accuracy has been achieved, with a 33% algorithm precision enhancement.

Check out our dedicated white paper here.